Shanghai Hanbell was established in 1996 and listed on Shenzhen A-share market in 2007. Jinan, Guangzhou, Nanjing and Chongqing branches have been set up one after another, and the subsidiaries of Zhejiang Hanson, Shanghai Comer, Hanbell HongKong, Hanbell Vietnam, Hanbell Korea and Zhejiang Comer have been set up one after another. All these reflect the achievements of HANBELL people's hard work in the past 27 years.

HANBELL PRECISE MACHINERY COMPANY 27 YEARS OF HISTORYAIMS TO OPEN

With the global fossil energy becoming more and more exhausted, the pollution is getting worse and the climate is getting warmer. Under the pressure of this severe energy situation, the solar photovoltaic power generation technology is making continuous progress. The world photovoltaic industry has entered a period of rapid development. PV industry is the most direct embodiment of "low carbon economy" among all new energy industries.

The vacuum business department of Shanghai Hanbell Precision Machinery Co., Ltd. has always adhered to the concept of low-carbon economy and environmental protection, and launched the dry screw vacuum pump DPS series for photovoltaic under this severe situation.

There are many technological processes and strict requirements in the photovoltaic industry. The main processes include crystal pulling, coating, cell interconnection, lamination and other steps. The DPS series of dry screw vacuum pumps for photovoltaic introduced by our company mainly plays a huge role in crystal pulling in single crystal furnaces.

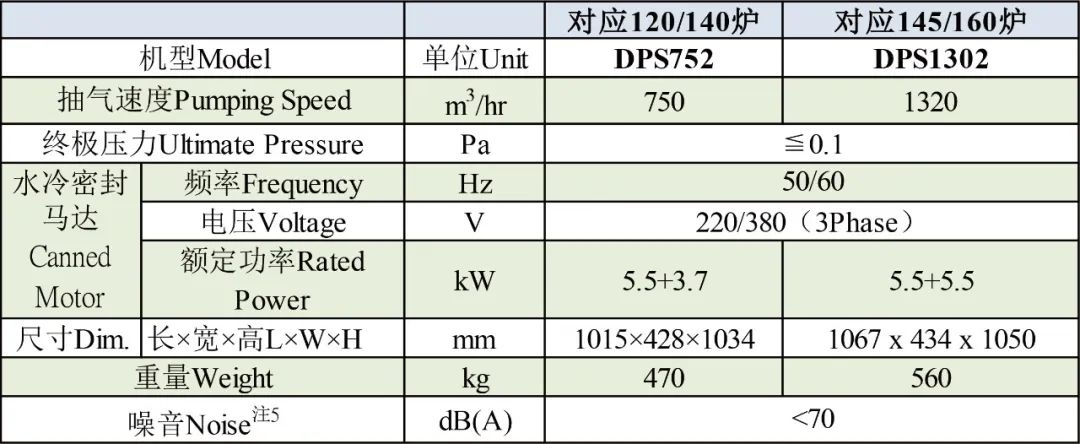

In the photovoltaic industry process, the crystal pulling process is particularly important. DPS752 and DPS1302 vacuum pumps are introduced for the crystal pulling process.

In the process, the filter tank uses a simple harmonic dust remover, and the exhaust gas is divided into two paths, one of which is the evacuation gas path, and the other is the channel for argon recovery in the process. In industrial application, the product has stable performance and high user evaluation.

Single crystal furnace DPS752/DPS1302

Performance parameter table:

On the basis of stable mechanical performance provided by Hanbell dry screw vacuum pump, we also provide a vacuum pump control system for the crystallization furnace. This control system integrates the function of converter PID to adjust and control the furnace pressure, cancels the inlet proportional control valve, and keeps the furnace pressure constant:

1) Reduce hardware cost: directly cancel proportional control valve to reduce cost;

2) Consumption reduction and energy saving: 592.3W of energy can be saved for a single boiler, and 128 degrees of energy can be saved during 216H operation time;

3) Reduce the operating temperature of the unit: the maximum operating temperature of the unit can be reduced by 26 ℃;

4) Improve reliability: it can reduce the volatilization of oil in the unit, reduce the wear of seals such as bearings, increase the service life and extend the maintenance cycle.

According to the user's use report fed back by the photovoltaic dry screw vacuum pump, it has achieved good social and economic benefits and achieved the following green mission:

1) Promoted the transformation and upgrading of photovoltaic production industry:

The use of dry pump to replace oil pump has realized argon recovery in the production process, saving argon resources. Through innovation and technical innovation, it has realized cost reduction and efficiency increase for photovoltaic production enterprises and improved production efficiency.

2) Driving green manufacturing of photovoltaic industry:

The vacuum equipment is maintenance free and oil replacement free, which improves the cleanliness of photovoltaic manufacturing equipment. At the same time, the fully sealed water-cooled motor is used, which has low noise, good sealing, extremely low leakage rate, safety and environmental protection.